Corrosion Resistance

for Grills and Outdoor Kitchens

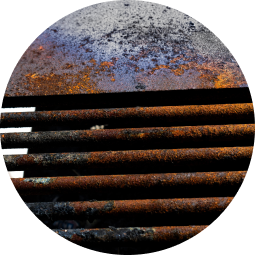

Corrosion, or rust, is a common problem for outdoor kitchens and grills. Their metal surfaces make them especially prone to corrosion due to the moisture and humidity of the air as well as the changing temperatures outdoors.

Grills and outdoor kitchens with proper corrosion resistance are more durable and tough than those without. Protecting outdoor cooking equipment from rust also ensures it stays aesthetically appealing. Rust and corrosive damage are unsightly, and preventing them keeps outdoor areas inviting.

Perhaps the most significant aspect of protecting grills and other outdoor cooking equipment from corrosion is food safety. Cooking on a rusted surface is not hygienic or safe, and getting cut from handling rough, rusted metal can cause tetanus.

Corrosion resistance for outdoor cookware costs more upfront, but it improves the quality of the equipment and extends its lifespan. Preserving the value of grills and outdoor kitchens is cost-effective in the long run. Keep reading to learn more about the value of corrosion resistance.

Understanding Corrosion

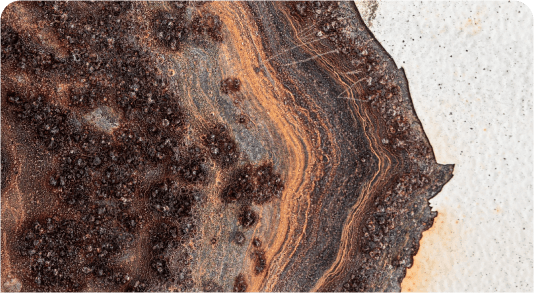

Rust, or corrosion, is a natural process that happens when metal surfaces are exposed to outdoor environments with moisture in the air. Over time, metal deteriorates because of the chemical reactions that take place. This process takes varying lengths of time and happens in stages.

There are several types of corrosion to review that specifically impact grills and other elements of outdoor cookware.

Types of Corrosion That Can Affect Grills and Outdoor Kitchen Components

For outdoor cooking, there are four main types of corrosion to be aware of that can damage and devalue various pieces of metal equipment.

Galvanic Corrosion

Galvanic corrosion is the result of two different metals being exposed to moisture in the air. The electrolytes in the moisture initiate the electrochemical reaction between the two metal types.

However, the different types of metal have differing electrochemical potentials, forming an electrochemical cell. The electrochemical cell causes the more active of the two metals to corrode at an accelerated rate. For a grill or outdoor kitchen set, this happens when metals like stainless steel and aluminum or cast iron are in direct contact. Localized galvanic corrosion occurs where they make contact.

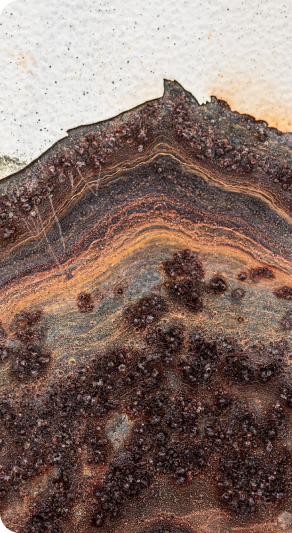

Pitting Corrosion

When the protective oxide coating used on many metals, including stainless steel, becomes damaged, pitting corrosion is likely to take place.

This corrosion is localized to the area where the oxide coating is damaged, creating dents, cavities, and small pits on the surface of the metal. When metal becomes pitted, it invites further surface irregularities and damage as the oxide coating receives increased damage. Over time, pitting can intensify, leading to reduced structural integrity and promoting further corrosion to the metal.

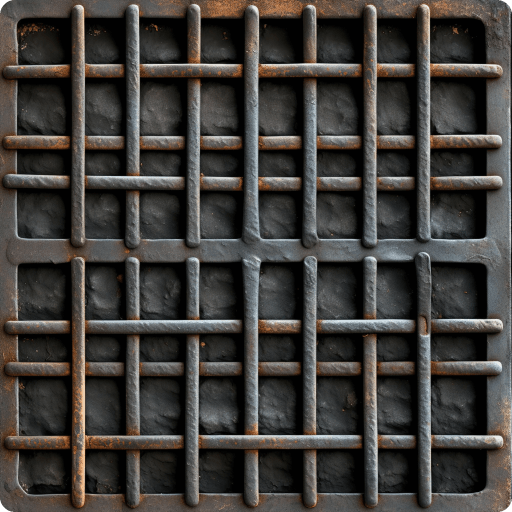

Crevice Corrosion

This type of corrosion mostly affects tight spaces and crevices in metal objects where moisture and oxygen can become trapped easily.

When these factors combine in a small space with no room to circulate, crevice corrosion easily takes hold. Crevice corrosion is particularly problematic because it tends to form in joints, overlapping sections of metal, and seams in outdoor metal structures. Grill lids, cabinets, and hinges on grills and outdoor kitchen equipment are especially susceptible to crevice corrosion. The stagnant areas that attract crevice corrosion can lead to extensive damage that’s hidden in small areas.

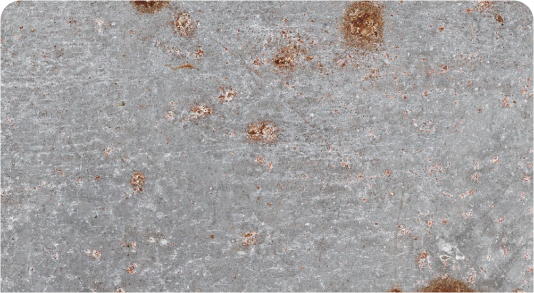

Uniform Corrosion

This type of corrosion is the most common, affecting the entire surface area of a metal item like a grill. Uniform corrosion shows an even level of rust across the item.

This corrosion isn’t as damaging or detrimental as other types of corrosion, like crevice corrosion, but it weakens metal evenly, causing damage in all areas. Not only can this affect the presentation and appearance of grills and outdoor cooking equipment, but it can also tarnish their usability and function.

Why Corrosion Resistance Matters in Grills and Outdoor Kitchen Components

Corrosion impacts the physical appearance of grills and outdoor kitchens, but it also shortens their lifespan. The destructive chemical process of corrosion damages the physical properties of the products in numerous ways.

Here’s a breakdown of how corrosion impacts metal cooking components when left in moisture-rich outdoor areas.

Performance

Corrosion damages various grill components to the point of diminishing their performance capabilities.

The stainless steel and cast iron components in pieces like burner tubes, grates, and heat diffusers can easily corrode and become uneven.

Cooking on uneven surfaces leads to unequal heat distribution, which can leave parts of your food burnt and other parts undercooked. Grilling on an uneven surface is dangerous and typically results in poor food.

Maintaining a grill or outdoor kitchen is also more challenging when corrosion affects ignition systems. Sometimes, corrosion is so advanced that starting the grill up at all is difficult. Even if it is possible to attain a flame, keeping it even and consistent is an added hardship when corrosion is present.

Heat Efficiency

Those who cook with corroded grills may notice they use more fuel than they would expect. This is because surface corrosion on grills and inside the firebox itself acts as an insulator, keeping the interior hot while the cooking surface stays cooler.

When corrosion reduces heat transfer like this, it takes more fuel to maintain a consistent cooking temperature. Higher fuel consumption leads to higher operating costs for the user.

This is one reason to spend more on properly protected cooking equipment that can withstand the potential corrosion that results from being left outdoors.

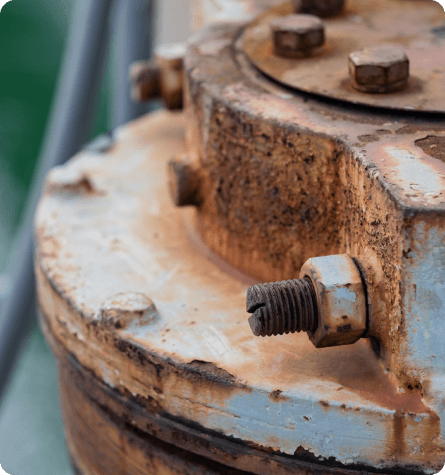

Structural Integrity

Between crevice corrosion and galvanic corrosion, it’s easy for grill components like frames and hinges to be weakened.

When corrosion forms in these nooks and crannies, it can quickly develop and spread without being noticed.

Grills with corroded joints are prone to warping, bending, and outright breaking. It’s unsafe to cook on a grill with structural damage as a result of corrosion because it could collapse at any time, potentially leading to accidents and injuries.

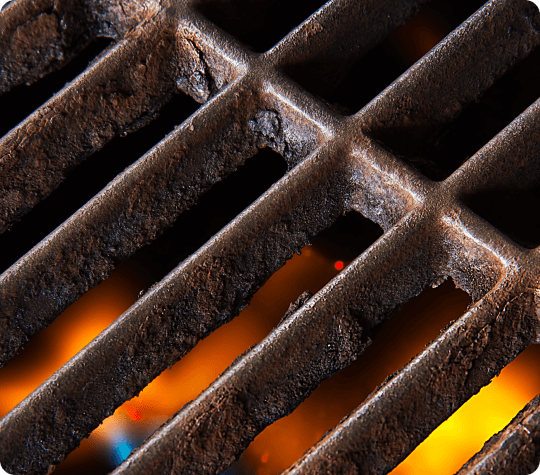

Rust Contamination

One of the biggest concerns when grills or outdoor cooking equipment become corroded is health and safety.

The rust that develops on metal grates, grids, and other cooking surfaces releases particles into the air that can cause serious damage. Not only will rust negatively impact the flavors of any food cooked on the grill, but it also poses a health risk for food.

Cooking on a rusted surface damages the tenderness of various meats. Rust, being an iron oxide, has a strong iron taste that most people find deeply unpleasant.

Aesthetics and Customer Perception

A significant draw for grills and outdoor cooking sets is their visual appearance. The luxury of relaxing and enjoying the outdoors whilst grilling up some delicious food is why most customers look for outdoor kitchen setups in the first place.

When corrosion and rust takes hold on a grill or outdoor kitchen components, the aesthetics of the items are damaged irreparably. Rust makes these items look worn out and dated, tarnishing the appeal they should have and making the entire outdoor space look worse overall.

Lifespan

The combination of the various effects mentioned previously equals a significantly shorter lifespan for grills and outdoor kitchen items that don’t have protection against corrosion. The degradation of metal surfaces over time leaves items prone to failure and deterioration. Pieces with corrosion are more likely to fail and fall apart, requiring replacements more frequently than items with corrosive protection.

Materials and Corrosion Resistance

Some of the most commonly used materials in grills and other outdoor cooking components include stainless steel, aluminum, and cast iron. These materials are all unique in terms of their characteristics and resistance to corrosion. Because of these differences, some are more suitable for outdoor use than others.

Let’s review the different materials and assess their various corrosion resistance levels.

How to Enhance

Corrosion Resistance

There are many ways to enhance the natural corrosion resistance of many types of metal, including the three we’ve explored above. Let’s discuss some helpful tips and methods for increasing the lifespan and corrosion resistance for various metal outdoor equipment.

Prevention

Possibly the best thing you can do for your grill and outdoor kitchen components is regularly maintaining them to prevent the build-up of corrosion in the first place. In this section, we’re exploring the different steps you can take to prevent the development of corrosion and rust in your outdoor equipment.

Regular Cleaning

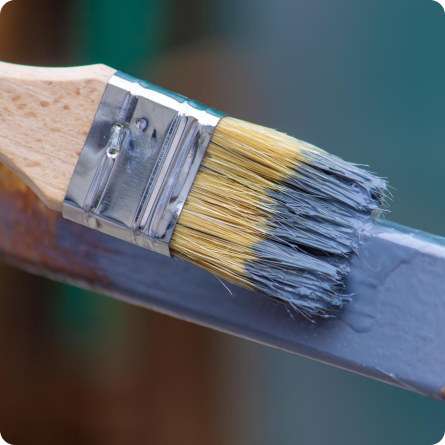

Regularly cleaning your grill and other outdoor components on a regular basis removes all manner of debris that can promote corrosion.

Food residue, dirt, soot, and grease can quickly build up in crevices and other structurally significant areas of your equipment and kick-start the corrosion process. When you’re cleaning, ensure you use the appropriate cleaners and brushes to avoid damaging or scratching your grill or outdoor kitchen components’ protective coatings.

Dry Thoroughly

If you leave your equipment dripping wet in the outdoors, you unintentionally welcome corrosion to take hold, particularly in hard-to-reach areas that can trap moisture.

Therefore, it’s imperative that you thoroughly dry your grill and outdoor cookware with a soft cloth or microfiber towel to get all of the surfaces completely dry. Pay particular attention to the joints and fine closures of your equipment.

Season Cast Iron

As we mentioned earlier, cast iron requires seasoning to stay in optimal condition. If your grill consists of cast iron components, regular seasoning will keep it in top form.

Vegetable oil or other high smoke-point cooking oils are ideal for creating the seal that cast iron needs to stay strong against corrosion.

The protective layer of the oil prevents moisture from getting to the cast iron and also improves its non-stick quality, making it easier to cook with overall.

Use Grill Covers

A high-quality grill cover is an excellent investment for preventing corrosion on your grill.

Weather-resistant covers can protect your outdoor kitchen components from rain, snow, and other potentially damaging elements in the outdoor environment. Grills and outdoor kitchens also have less direct exposure to atmospheric moisture, minimizing the likelihood of corrosion even further.

Which Treatments and Coatings Enhance Corrosion Resistance?

This section explores which specific treatments and coatings can protect metals from corrosion, as well as explaining how these protective coatings work.

Let’s examine the possibilities with metal treatments and coatings.

Powder Coating

One popular way to protect metal surfaces from damage is with powder coating. This coating applies a durable, protective finish that keeps metal safe from wear and tear.

Powder coating is achieved by electrostatically charging dry powder particles and spraying them onto metal. Manufactures heat the metal after the coating is applied, melting it out into a continuous layer around the entirety of the metal surface. Beyond corrosion resistance, powder coatings also provide a defense against impact resistance. Another appealing aspect of powder coating is that it comes in various colors and textures.

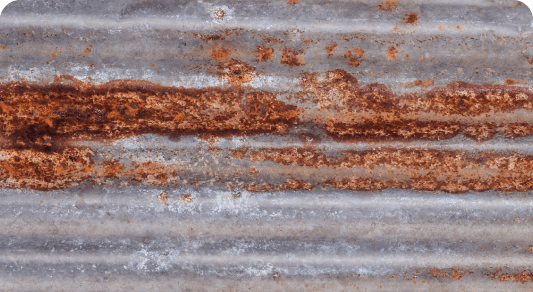

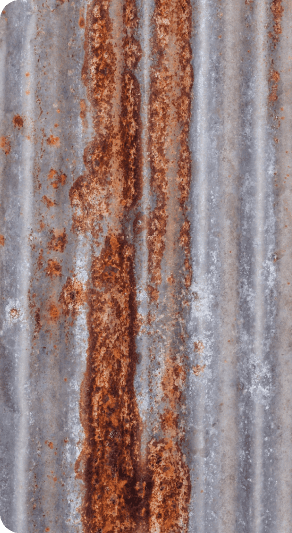

Galvanizing

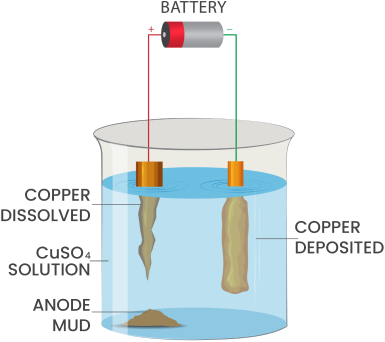

Galvanization is another common approach to protecting metal surfaces against corrosion and other damage.

This method is usually used for steel or iron. The metal surface is covered with zinc to prevent corrosion.

Frequently used for grills and outdoor kitchen cookware, galvanizing causes the zinc coating to be a sacrificial anode which keeps corrosion from reaching the steel or iron beneath.

Anodizing

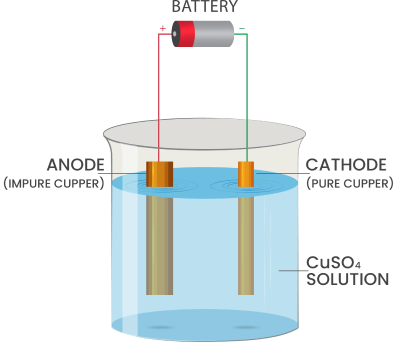

This is a more unique form of corrosion resistance protection, requiring an electrochemical process typically used on aluminum.

Anodizing involves converting aluminum surfaces into thick, porous oxide layers. Oxide layers provide an excellent, durable defense against corrosion and other common causes of surface damage.

It’s also possible to seal the porous layer, using different sealants to gain higher durability.

Electroplating

Another type of corrosion protection is electroplating. This isn’t typically used for cooking equipment, being more common for chrome, copper, and nickel metal items.

The metal is immersed in a metal ion solution, followed by the application of an electrical current. A thin layer of metal ions clings to the substrate of the metal object, creating a thorough coating that’s resistant to corrosion.

Ceramic Coatings

Ceramic coatings are more common for cookware than electroplating. Ceramic coating offers a high level of hardness protection, as well as chemical resistance, thermal stability, and – obviously – corrosion resistance.

Some cookware items use ceramic coatings because of its suitability for high-temperature uses.

Paint and Enamel Coatings

This type of metal coating is very aesthetically appealing. It prevents moisture from making contact with the metal beneath, reducing the chances of corrosion beginning to form.

Manufacturers use high-quality paints and enamels to create strong coatings that can properly protect metal equipment from environmental damage.

Organic Coatings

There are several forms of organic coatings that are applied to metal surfaces as liquid paints. Some organic coating examples include acrylics, epoxies, and urethanes. As they cure around the metal surface, they create a protective film around a metal item to increase its durability and significantly decrease the chances of corrosion taking hold.

What to Look for When Buying Corrosion-Resistant Grills and Outdoor Kitchen Components

There are numerous factors you can look for when you plan to buy grills and outdoor kitchen components to ensure you get an excellent piece of corrosion-resistant equipment that has a long lifespan.

Here’s a rundown of tips for getting the best equipment for your needs.

Material Quality

Perhaps the most crucial aspect of getting the best grill and outdoor kitchen components possible is keeping a close eye on the quality of the materials used in its construction.

Stainless steel is an excellent choice for its corrosion resistance, particularly high-grade stainless steel like 304 or 316 for example, is an excellent material for grills and outdoor kitchen cookware.

Beyond stainless steel, there are other corrosive-resistant materials, like coated aluminum or properly seasoned cast iron, might be preferable for specific components or aesthetic styles.

Corrosion-Resistant

Coatings

Components that aren’t naturally corrosive-resistant should have an effective and thorough corrosion-resistant coating. For example, when you look for grills, you should be able to find items with powder coatings, galvanized coatings, or anodized coatings to ensure corrosion doesn’t easily make its way into the nooks and crannies of your cookware components.

Look for corrosion-resistant coatings when shopping for grills to protect your cookware.

Design and Construction

Poorly constructed grills and outdoor kitchen components are easy to spot if you take a closer look. Always take your time when you’re looking at items to ensure they’re well designed and constructed before you decide to make a purchase.

Check the welds for their quality, ensure the parts fit well together, and maneuver the item around so you can get a sense for its structural integrity.

Weather Resistance

No matter what the weather is like where you live, you should consider how it could impact a grill or outdoor kitchen on your property.

Components like seals and gaskets should be weather-resistant. This can mean special coatings or protective covers that shield the finer components from atmospheric moisture and humidity.

Cleaning and Maintenance

Each grill and outdoor kitchen has its own cleaning and maintenance system needed to keep it operating efficiently and safely.

Try to find a product with a simple routine that’s easy to keep clean and strong. Low-maintenance items are typically well-made and have long lifespans free from corrosion, pitting, and surface irregularities.

Brand Reputation

It’s rarely a good idea to buy from a brand you’ve never heard of whose products seem lackluster. Instead, find brands known for their high-quality products, particularly any brands that emphasize the importance of corrosion resistance in outdoor kitchen components. Online reviews and word-of-mouth experience with brands is typically a reliable indicator of their reputation and quality.

Warranty

The quality of an item’s warranty usually lines up with the quality of the item itself. The warranty tells you how much confidence the manufacturer has in their products. Buying an item with a good warranty ensures you have protection for your investment that can get your money back if you’re dissatisfied for any reason.

Certifications

and Standards

You can get a superior quality grill or outdoor kitchen component if you look for items that have specific certificates to confirm they meet certain industry standards. Any item with certifications specifically for outdoor use is especially appealing and should rank highly on your shortlist.

Components

and Features

You can save yourself some trouble by paying close attention to each specific component used in an outdoor kitchen set. Look for sets with corrosion resistance in all crucial areas like joints, drawers, burners, and grates. Any other accessories should also be corrosion resistant and protected against a range of weather types.

User Reviews

This applies to brand reputation and the reputation of specific items. Look for genuine customer reviews to understand how the grill or outdoor kitchen performs in real-world scenarios. If you spend some time looking for reviews that mention the corrosion resistance of the item, you’ll be able to decipher if it lives up to the hype of its marketing copy or if it’s not all it seemed.

Budget Considerations

Finally, your budget should be a significant consideration for getting the best grill you can. The best quality grills and outdoor kitchen components with effective corrosion resistance may come at a higher price than average outdoor cookware. Consider the benefits of having high-quality pieces that have longer lifespans against your budget and decide if you’d be willing to invest more in the quality and longevity of your outdoor cookware.

Conclusion

Overall, grills and outdoor kitchen components with effective, high-quality corrosion resistance can last significantly longer than ordinary outdoor cookware. Corrosion poses a serious threat to the stability and functionality of grills and outdoor kitchen cookware items. It’s very challenging to remove corrosion and rust once it has set in, and preventative care is the best way to avoid serious corrosive development in your outdoor metal cookware.

If you want reliable grills and outdoor kitchens, it’s worth investing in thorough corrosion-resistant materials made by reputable brands with reasonable warranties. For the best grills and outdoor kitchen components that are crafted to last, explore our range of products featuring grills, outdoor kitchens, BBQ accessories, and more.

Why is corrosion resistance important for grills?

Corrosion resistance is important for grills to ensure their longevity and durability. Grills are exposed to different weather conditions, and corrosion resistance helps prevent rust, which extends the lifespan of the grill.

What materials are commonly used in grills for optimal corrosion resistance?

Stainless steel and aluminum are commonly used for grill construction because of their natural resistance to corrosion. These materials offer protection against rust and corrosion from moisture and outdoor elements.

How can I maintain the corrosion resistance of my grill?

Regular cleaning and proper storage are important for maintaining corrosion resistance. It is recommended to remove grease, food particles, and moisture from the grill surface, and to use grill covers when not in use to protect it from the elements.

Do different parts of a grill have varying levels of corrosion resistance?

Different components can be made from other materials, each with their own level of corrosion resistance. It is important to consider the construction of important parts such as burners, grates, and exterior surfaces in order to ensure complete protection.

Are all stainless steel grills equally corrosion-resistant?

The corrosion resistance of stainless steel can vary depending on its grade and composition. Higher grades, such as 304 and 316 stainless steel, tend to have greater resistance to corrosion compared to lower-grade stainless steel.

How does exposure to salt air impact the corrosion resistance of grills?

Salt air, commonly found in coastal areas, has the potential to speed up corrosion. It is recommended to select grills that have enhanced resistance to corrosion for coastal regions or to take additional measures such as regular rinsing and applying protective coatings.

Can the use of certain cleaning agents affect the corrosion resistance of a grill?

Certain cleaning agents can potentially harm the protective layers on the grill’s surface, which can lead to a decrease in its resistance to corrosion. It is advisable to utilize gentle, non-abrasive cleaners and adhere to the cleaning instructions provided by the manufacturer.

Is powder coating an effective method for enhancing corrosion resistance?

Powder coating can provide an additional layer of protection against corrosion by acting as a barrier that prevents moisture and corrosive agents from reaching the underlying metal surface, ultimately extending the life of the grill.

What role does proper ventilation play in preventing corrosion in grills?

Proper ventilation is important for reducing moisture buildup and minimizing the risk of corrosion in the grill. It is recommended to choose a grill design that includes adequate ventilation features to ensure optimal air circulation.

Are there any aftermarket products that can enhance the corrosion resistance of a grill?

There are aftermarket products available for grills, such as protective sprays and coatings. These products can provide extra protection against corrosion and are usually simple to apply for added convenience.